Cultivating the Right Roots: How to Pick the Right Carpet Based on Weight and Pile

Save this blog post for later!

Carpet. You either love it or hate it. At least that’s based on our experience helping homeowners find what the right flooring material could be for their lifestyle. For some, the cost of carpet just doesn’t seem like a valuable investment and can often feel like something that some homeowners need to replace more often than others. And I know what you may be thinking, some instances homeowners install the most budget-friendly option they felt comfortable with without taking into account the quality of the carpet. While quality of the carpet can absolutely play a role in the life of a carpet and should be something everyone takes into account when shopping for flooring, sometimes even the highest quality of carpet will wear down really quickly. In some instances, it’s not you or the carpet’s fault at all—rather, it’s just unfortunate placement of the carpet.

For this discussion, we are going to c-o-m-p-l-e-t-e-l-y ignore some of the most common directing points that people often find themselves in when picking out the right carpet. That’s right, we are going to completely ignore the fiber type, dye process, and other manufacturing details. No polyester versus nylon discussions here. No “Solution Dyed is the way to go!” arguments allowed. No environmental pivoting points. Instead, we are going to look purely at the ounce weight, density, and pile height.

Definitions

Let’s get a couple of terms defined and out of the way before diving into anything. We are going to be getting into some math later to show why certain carpets work better in certain rooms or places in a home later, so the better we understand certain concepts, the easier the math will be. Don’t worry, though, we will walk you through the entire process step by step to make sure you can follow along if you ever need to.

Density

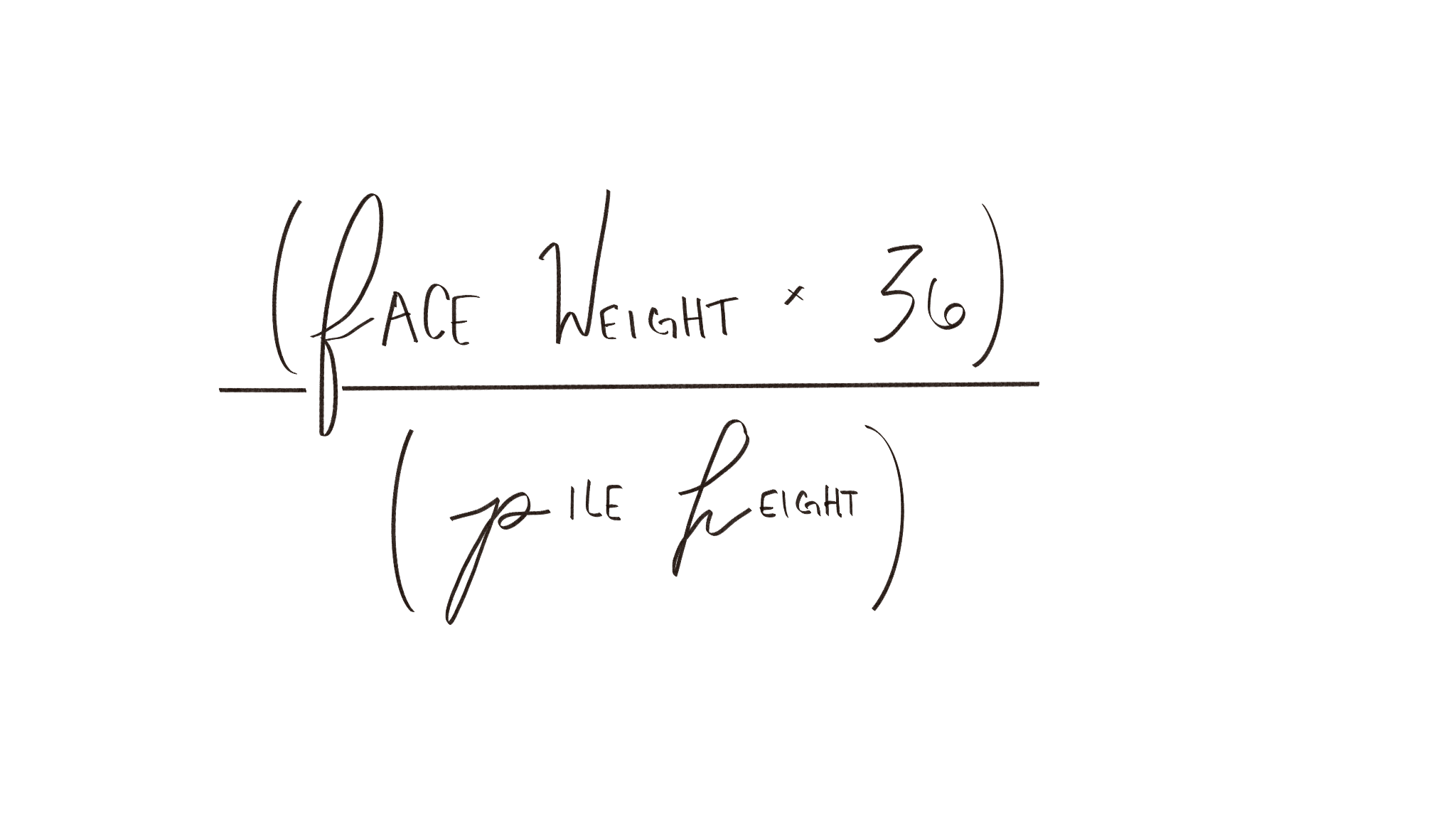

The amount of pile yarn per area of carpet. Density can also refer to the closeness of the carpet tufts. A carpet’s density affects the durability, comfort, memory, and overall performance of the carpet itself. This number is calculated using a mathematical formula, as shown below.

Essentially, you take the face weight and multiply that by 36, then take that value and divide it by the pile height. 36 will never change in this equation because this transforms the face weight value of ounces per square yard to ounces per cubic yard. Pile height is a value in three-dimensions, so we need to make sure the ounce weight is also represented in the same dimensional space.

Carpet Density Formula

Face Weight multiplied by 36, then divided by Pile Height

Face Weight

The number of ounces of fiber per square yard in the face of the carpet—the side of the carpet you can see and walk on once installed. Note that the actual backing of the carpet, the piece that holds all of the pile yarn together in place, is not included in the Face Weight value. When talking about a carpet ounce, this is what people are referring to, the face weight. The ounce weight of a carpet does have an influence on the overall durability and performance of a carpet, but it is not always the best determining characteristic that says whether or not a carpet will be durable. Pile height has a large role in indicating the durability of a carpet, hence why the importance of the density equation for carpet. Density takes both values into account and can tell the full story, whereas face weight can only tell part of it.

Pile

This is the visibly surface of the carpet. They can come in various styles, like looped and cut. Looped will not have the fuzzy look or feel because the end of the fiber is tucked back into the carpet, whereas the fuzzier carpets are cut after being tucked back in, leaving a little bit of fraying to provide the soft feel.

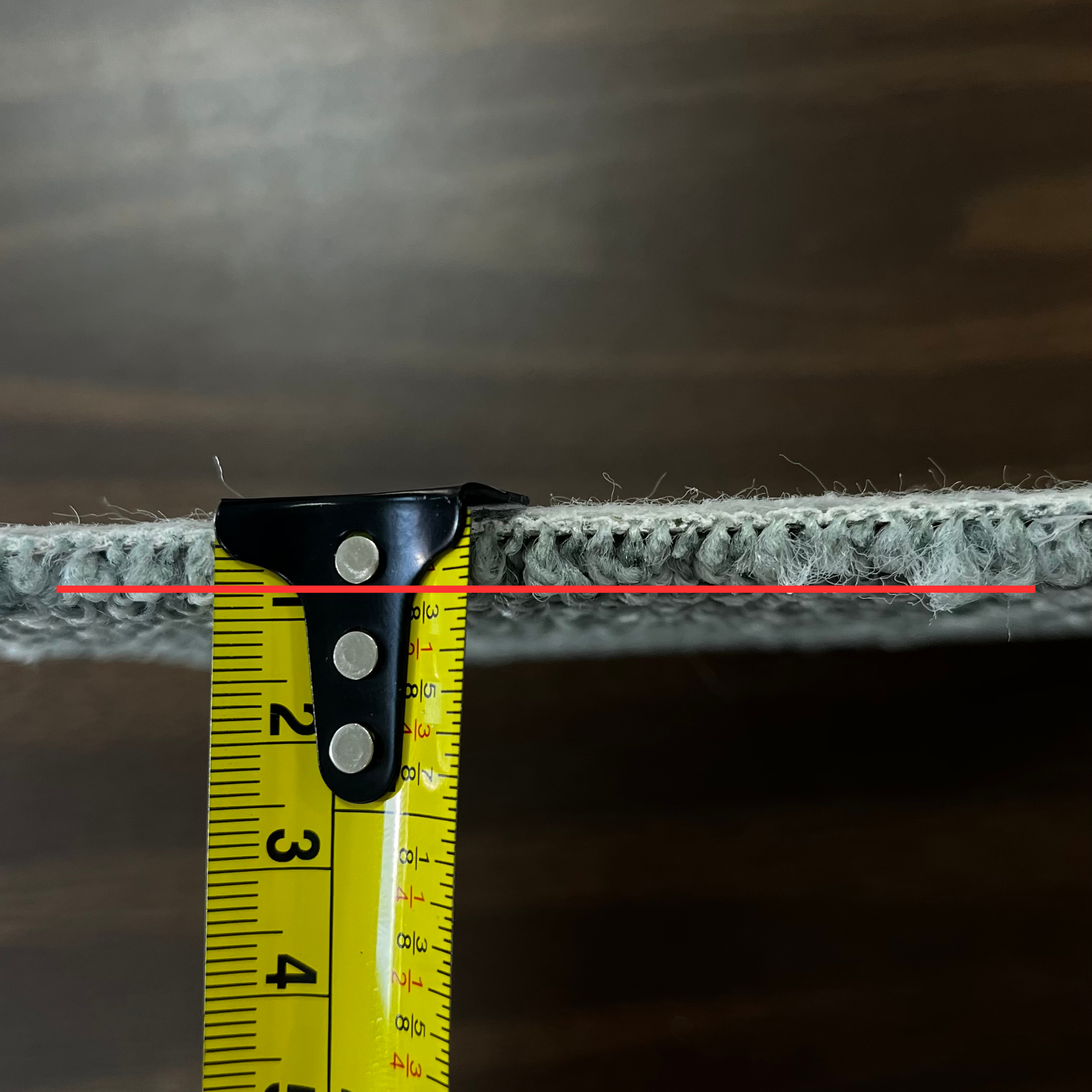

Pile Height

The length of the tufts of yarn fibers measured from the primary backing top to the tips of the pile fiber—basically the visible length of the fiber when holding up a sample. For the best measurement, the pile itself should be gently extended and not stretched out, as this is its most commonly seen form. Rarely is the fiber actually stretched out or crushed when first installing.

Twists

The number of times a yarn is twisted around itself per inch, usually in reference to cut piles. The more twists a carpet has, the more durable it will be. Essentially, think of a rope, where the more the strands building the rope are twisted together, the harder it will be to break through the rope itself. There are actually two different names that give you more information about the twist type: frieze and saxony

Frieze

A high number of twists per inch that is greater than or equal to five. When you twist the yarn fibers five or more times, the yarn typically ends up curling in on itself because the tension created by each twist. Because of this, vacuum lines won’t be visible. As such, if you are looking for a carpet that will not show vacuum lines, try to find one that has a higher number of twists.

Saxony

A low number of twists per inch that is less than or equal to four. Unlike a frieze twist, a saxony twist will be more likely to stand upright and fluff out a little bit. The fibers will be softer, but they will be less dense, thus playing a role in the face weight of a carpet. Because of its fluffy nature, vacuum lines are more likely to appear. Be careful, as some manufacturers will trim the fibers are twisting to make the carpet feel softer and have a fuzzier look. The carpet will now be less durable than before, but that is not always a bad thing.

Definitions in Practice

The least durable carpets are more likely to have a high pile height, saxony twist, and a low density value. Because of the lower overall density value, the carpet is going to have less memory (it is less likely to bounce back after being crushed), show signs of wear, and sometimes even fail to bounce back after normal, routine vacuuming. Some carpets that get fluffier over time were probably trimmed by the manufacturer to give an initial fluffy feel, and the vacuum sadly tufts them out over time. (That is not an excuse to not vacuum those carpets! That will actually make them wear faster, so still vacuum!)

The most durable carpets will be low pile height, looped, and a high density value. These carpets have a strong memory where they are more likely to bounce back after being crushed and less likely to show signs of wear. That’s why commercial carpets are so strong: the pile height is so low, and the fibers are tucked into the backing so tight that they are going to last years. More often than not, commercial properties with carpet tile replace the carpet because the tiles look and feel gross, usually not because the fibers themselves have been shredded to bits over the years.

The Math

Let’s take a look at a couple of carpets together and see the math in action.

Anderson Tuftex Breeze Block in Blue Fern

We have a small sample square of Anderson Tuftex’s Breeze Block in the color Blue Fern, and this small sample will work as a good demonstration for our first example. Breeze Block is a high performance, high quality nylon with Anderson Tuftex’s patented SoftBac backing, which helps with water proofing, spills, and stains. The yarn fibers are patterned loop, where different colored yarns are looped into the backing to form a plaid-esque repeatable pattern. Though the patterned loop information is not neccessary for the denisty equation, knowing that it is looped can be helpful information; we already know that this carpet is probably going to be more durable because of the pile is looped and the tip of the yarn will be protected from additional wear-and-tear.

When looking at Breeze Block from the manufacture's website (view here!), we can see that the carpet has an ounce weight of 36 ounces per square yard, which is one of the numbers we need for the density equation. Ounce weight can be difficult to figure out if there is not a clear way to know the density of the carpet itself. Sometimes the weight is not listed on the sample board, meaning you have to find the ounce weight online through the manufacturer's website. A little tip, some carpet manufacturers put the ounce weight in the product code somewhere. For instance, Dream Weaver carpets sometimes, though not always, have the ounce weight in the last two digits of the style code (Not the color code!) In this case with our square sample of Breeze Block, the face weight is 36 ounces per square yard, as stated on the Anderson Tuftex website, but the style code for the same carpet is ZZ291. The sample card does not have the face weight labeled on the back either, so the only accessible way to know is to find the carpet online. Even then, that may not be possible, so if you want to know the ounce weight, the flooring store may know or will be able to reach out to the vendor to confirm quicker than you reaching out to them directly.

When doing the equation, we also need the pile height for the carpet, which is not something outright listed on the website unlike the ounce weight. There is a specifications guide on the webpage that does have the pile height listed, but this is not always the case. There are some carpets in the market that do not have the detailed specifications spreadsheet easily accessible, and as such, it can be handy to know how to measure the carpet yourself in case reaching out to the manufacturer will be too time consuming or difficult to do.

To do so, make sure the carpet you are measuring is in its standard condition—not crushed or overly stretched. Then, take your measuring device and measure from the bottom of the fiber to the top. In this case, we measured close to a third of an inch, which is what the pile height is listed as within the specifications guide for Breeze Block.

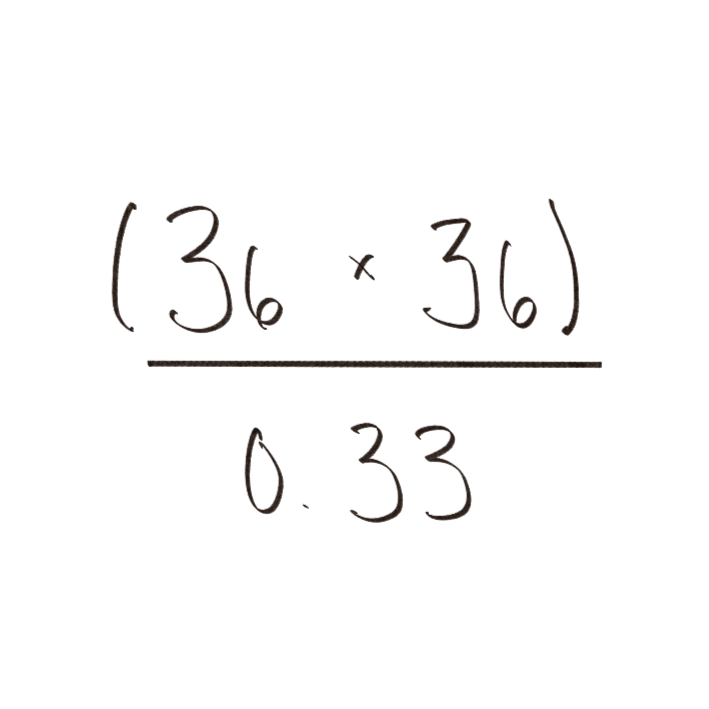

Now, for the math. We take the face ounce, 36, and multiply it by the constant, in this case, also 36, to turn the ounce weight into a cubic yard measurement; this equals 1,296. Now, we will divide 1,296 by 0.33 inches, which equals a rounded down 3,927. We do not need the decimal value and can purely work with whole numbers. That’s it! That’s all of the math done, quick and simple!

Anderson Tuftex Breeze Block Density

36 multiplied by 36, then divided by 0.33

Now… we have this number that represents the density. Without context, this number is not helpful. However, density has a massive range depending on the ounce weight and pile height of individual carpets. As such, there is a guide that can help you understand what that density means and where it performs the best—in other words, what carpet densities should be installed where.

Value Output: 1800-2500

If the final density value is within 1800-2500, the carpet is not dense and would work best in low traffic areas, such as basements and guest bedrooms. Soft, cozy carpet works really well in these types of situations because the carpet itself is rarely stepped on or touched, maybe once a week to vacuum and maintain on average. These are normally extremely budget-friendly options because the ounce weight is low.

Value OuAtput: 2000-3000

Anywhere with a density output of 2000-3000 works well for places that have a little bit more foot traffic than rarely walked-in areas but still ask for a softer, gentler atmosphere. Places like bedrooms work well for a carpet that has a density around the 2000-3000 range because of the extra durability compared to the lower density options.

Value Output: 2500-3000+

A density rating between 2500-3000 or more perform best in high traffic areas, such as living rooms and offices. Furthermore, because the density is higher, roller wheels are less likely to cause wear-and-tear, or at the least a milder wear, over time than carpets with a lower density. Depending on the pile height, the yarns may still get stuck within the roller wheels, so it can be a good idea to try a roller wheel on a sample to see how it feels before selecting a carpet if roller wheel options are a priority for you.

Value Output: 3500+

A value of 3500 or more will be your densest carpet and will therefore take the best abuse to foot traffic. Areas like stairs and hallways receive the highest foot traffic in any home by far, meaning any carpet in these areas are more likely to show signs of wear over a shorter amount of time. As such, areas with a higher density, a tighter weave or loop pile will wear the best over time. Furthermore, stairs and hallways are areas that are the most likely to face negligence and will not be vacuumed near as frequently as they should—more often than not, vacuuming 2 or more times a week at a minimum is essential, even with high density carpets. A higher density value will be able to pull its weight better compared to anything with less value when neglected, but that is not an excuse to not maintain the carpet as frequently.

Back to the Carpet

Going to our Breeze Block sample, the density value for the carpet is 3,927. Alongside the loop construction, Breeze Block will perform exceptionally in extreme traffic areas, like stairs and hallways. That isn’t to say it won’t perform well in anything with less foot traffic! If the color and pattern of the sample is something you love and would like elsewhere in the home, there is nothing stopping you from putting that carpet there. Breeze Block simply has the ability to stand against higher levels of wear-attempts than other carpets.

Another Example

Let’s take a look at another example: Fabrica’s Luxe in Pumice (view webpage for Luxe here!). Similar to Anderson Tuftex’s Breeze Block, Luxe is a carpet made with the Dixie Group’s patented EnVision Nylon, which is a highly durable nylon that is more stain and pill resistant than other quality nylons in the industry. Luxe has a cut pile construction, meaning the carpet pile has been cut to give a fuzzy look and feel.

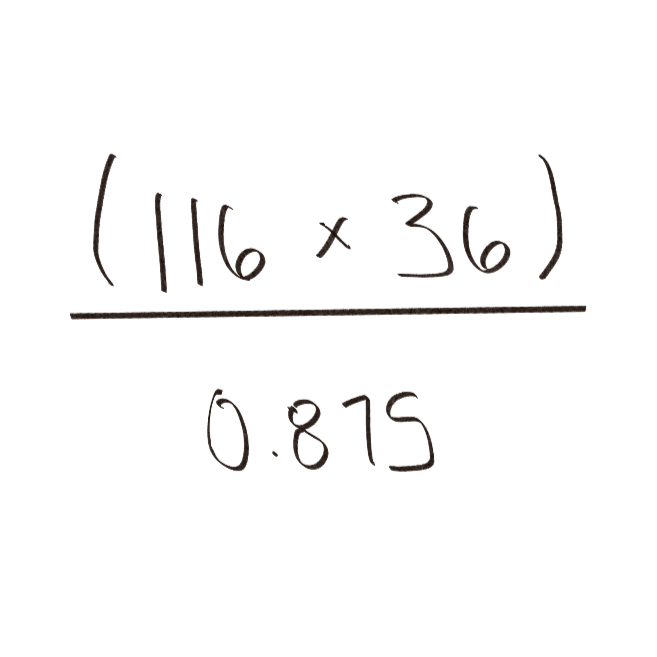

As for the stats we need, Luxe has a face weight of 116 ounces per square yard and a 7/8 inch pile height—a thick and soft carpet, for sure! (Especially when industry standard is 80 ounce!) Let’s go ahead and put our information into the carpet density equation: multiply 116 and 36 together, and divide that value by 0.875 (the decimal conversion for 7/8 inches). Our total ends up being 4,773.

Fabrica’s Luxe Density Calculation

116 multiplied by 36, then divided by 0.875

Taking our density value and placing it within the value output information above, we see the carpet fits within the high traffic area category, and it even beats out Breeze Block in terms of density. Technically speaking, you could probably install Luxe on a set of stairs simply based on the density value and performance suggestion, but realistically, this extremely soft and shaggy carpet should not be installed on stairs. Vacuuming such a thick carpet can take significantly longer than less dense carpets, and because stairs are already hard enough to vacuum and are thus more likely to face neglect, having a shaggy carpet installed on stairs may not be the best option. However, the density of the carpet shows us that despite being shaggy, the carpet is extremely durable thanks to the face weight. Dropping the face weight down to 100 for a hypothetical situation drops the overall density of the carpet to be around 3,200, which makes a difference in durability—though at that high of a face weight still, you probably wouldn’t notice too much of a difference, unless the carpet is on stairs.

And there you have it! Finding the density of a carpet can come in handy when looking at your options, as knowing the density can help you find what will be more likely to fit your needs and investment. Installing a super plush, more expensive carpet works wonderfully in some areas, but having that same carpet in an area that has low foot traffic or extremely high foot traffic may not make sense financially for some homeowners. On the other hand, finding what carpets are more likely to perform better in extremely high traffic areas can be easier knowing what density you need to look for. After doing a couple of calculations yourself, you’ll end up being able to visually tell what carpets work well in what situations without having to measure anything.

Naturally, there are other factors that can come into play, such as fiber type, dye-process, and color, and ultimately sway our decisions. However, knowing what factors play into the physical durability of a carpet, not the stain resistance or other features, can help steer you into the right direction to pick what makes sense for your lifestyle, where you are installing it, and what you are looking for in terms of investment.