Learning the Art of Bonsai: Click-Together v. Glue-Down v. Loose Lay LVP Edition

Flooring installation methods. There are so many methods out there, and each one has its pros and cons. Take a hardwood sand-and-finish installation for instance. Hardwood installation can be glued, stapled, screwed, clicked-together, floated, and any combination of the mix. Luckily, LVP is usually only has three main installation formats: Click-Together (Rigid Core), Glue-Down, or Loose Lay.

We’ll go down the list of what each one is, the pros and cons of each, what situation each preforms well in, and our overall professional opinion. Let’s start with the most popular among the DIY-er’s favorite method: click-together, or also known as rigid core.

Click Together

Click-together products are exactly what they sound like: planks that, well, click together and lock into place. There are multiple types of clicking methods, like angle/angle and drop/lock. We won’t be going into the differences of them here, but you can check out the definitions of each of them in our hard surface flooring glossary here. Essentially, the concept remains the same between the different locking mechanisms, where there are different keys, if you will, between each board that connects with a certain keyhole slot on another board. Each board has the key one on side and the keyhole slot on the other, and when interlocked together, they create a floating floor. In other words, a click-together floor acts like a giant puzzle and is floating over a subfloor.

Pictured is the locking mechanism of a click-together (AKA rigid core) product.

Pros of Click-Together

Because the product does not need to be adhered to the floor, click-together LVP products work well for a temporary floor. Depending on the floor underneath, sometimes you can install right on top of whatever is already there, though that isn’t always recommended. Instances where you want to sand-and-refinish hardwood floors in your home but aren’t ready to go forward with that process, click-together LVP could be a good alternative while you wait to refinish your existing floors. That makes the product seem like a strong contender for entry-level flooring installation. Can’t afford to refinish your floors either by renting out the equipment for it or hiring the process out to someone else but can afford a cheaper floor and a weekend or two? Click-together may be the way to go because of that. On the flip side, because it is a temporary floor, removing the planks can be easy as well. When you are ready to refinish that floor underneath, ripping out the puzzle will be a breeze compared to a product that is glued-down.

Click-together products are also usually either a WPC or a SPC, usually the later of the two, which means the vinyl also has either wood (WPC) or stone (SPC) composite mixed in with the plastic. These products are therefore extremely rigid compared to products that are pure vinyl, hence the common name Rigid Core. That means the product itself won’t bend or change shape overtime, at least not easily. Temperature and humidity can still play a role in the shape of a plank if not maintained and controlled, as discussed here. Any subfloor imperfections won’t be visible through the floor because it is so rigid. Any humps, dips, cracks, or other imperfections that can naturally form on the subfloor overtime will not be noticeable.

If you are worried about VOC emissions during the installation of the product, don’t worry, there are none! There are no smells or gases that are emitted during the installation process, so if you have health concerns surrounding VOCs during or post the installation or are looking out for the environment, click-together can be a safe option.

As a product itself, click-together tends to have a larger price point than other products, with some extremely budget friendly at $1 a square foot and others upwards of $6 a square foot, now boarder lining engineered wood price point territory. From a pure product perspective, without including the labor or other materials that each LVP may require, rigid core can be more of a budget-friendly, low cost alternative.

Cons of Click-Together

For some situations, the pros of a rigid core product can outweigh the cons. Yet… There are still a lot of cons you should be aware of when looking at flooring options.

For starters, let’s start with the last point of the pros. Though there may be budget-friendly options, quality is not always reflected in the price. However, sometimes a cheap, $1 a square foot floor can still last as long and hold up well compared to a $4 a square foot floor of the same product type (like a click-together with the same locking mechanisms to keep the comparison as close to apples to apples as possible, though that’s not quite possible.) if the cheaper of the two products is well taken care of by stable environmental factors and proper routine cleanings. We are going to completely ignore that possible price difference here and for each of the options, so don’t think that’s where we are going with this point!

We are talking about the underpayments, labor, and waste calculations here. Most rigid core products require a moisture-barrier underneath, and 9 times out of 10, that is not a part of the product itself. Even if it is, manufacturer's and trustworthy flooring installers still highly recommend putting one underneath, unless outright stated not to within the warranty information. Karndean Designflooring, for instance, is manufacturer that explicitly says no to putting any underlayment outside of their acoustic pad underneath their rigid core products, and if there is one placed, the warranty will be voided. Most others do require something, and ultimately, it comes down to what the backing is of each plank and what the product is made out of. Karndean’s Rigid Core is a virgin vinyl, meaning there are no additives at all. Republic Floors, on the other hand, have differing types of limestone mixed in with the vinyl, and limestone reacts to moisture, meaning a moisture or vapor barrier is required. The cost of the product usually does not include this vapor barrier, and depending on what is needed for the space the product is going to be installed in, estimate another $0.50 to sometimes even $2-3 more per square foot when including the vapor barrier. Not to mention the frustration that can go on when installing over a vapor barrier, as it is usually a plastic like a tarp that you cannot get stuck in between each plank, or else the barrier becomes useless.

Though the cost of the vapor barrier is relatively minimal, that’s the least of someone’s concern when it comes to cost in all reality. Labor and waste for a rigid core product go hand-in-hand. Remember earlier when we said each plank has a key on one side and a keyhole slot on the other? Well… if the product has to be cut down to fit around a corner, to properly fit around an edge or a cabinet, or in any other instance where you absolutely have to cut a board, that leftover piece is now altered and cannot be used elsewhere, unlike a glue-down or loose lay option. That piece is now trashed and cannot be used for the floor (Thought they do make for good coasters and other decor pieces!) That means the labor of cutting a piece can cost more than other options, and more waste is required because waste cannot be used elsewhere when installing. Even if you are installing yourself and not hiring anyone else to install for you, that means you will need to buy closer to 10-15% waste instead of the glue-down and loose lay waste estimate of 7-10% on average. Your savings per square foot end up being eaten up by the waste that is normally required to make sure you have enough to install in a room in the first place.

Speaking of labor, a good flooring installation requires floor prep. The subfloor needs to be as flat as possible, no matter what the subfloor is made out of, because any imperfections will lead to a product changing shape, have moisture problems, or otherwise cause balance problems. We believe and know that prepping a floor is what makes a flooring install go from a first-time flooring DIY to high-end installation, even if it is the exact same, extremely cheap and budget-friendly option. This is because the subfloor is primed and prepared for not only a new floor but for what natural events might happen, like moisture going up from the basement concrete subfloor. If the subfloor is ready, then the new floor will be more likely to succeed and outlast your lifetime expectations for that material. Now, you may feel like we are yapping, but remember the point awhile back saying that because click-together floors are rigid, you won’t be able to see subfloor imperfections? Though that in and of itself can lead to major problems, the fact of the matter is that the flooring is extremely rigid. You could place a plank between two humps in a subfloor and not notice the humps there at all when walking on it, but now the floor is literally floating and not resting ontop of a surface. That plank cannot hold near as much weight in the center as it can on the edges, which means, well… overtime, the board will warp, crack, and even break in half. The subfloor has to be even closer to perfection than other installation methods, which means more time and labor is spent towards prepping the floor, whether you do it (for those finance gurus out there, the opportunity cost!) or a professional does it. The cost of prep is so much higher than others because of one of its selling features, sadly.

Moving on from the install and to the performance of a click-together product, you already have to be careful with things like rolling chairs, dragging furniture, furniture weight--really anything that could put pressure on the edges of the plank where the mechanism is at. Roller chairs can put enough force to pull boards apart, and when they are pulled apart, the mechanism breaks. Same idea with dragging furniture. If something is too heavy without providing support to the furniture piece and/or the floor, that weight puts a lot of pressure on the boards and can thus snap. That's why you want a thicker product. But again, not too thick because now the board can't adjust to any changes in the room or subfloor. It’s like going back to the last point, If a lump forms in the subfloor and a really, really thick product (say, 14mm thick) is over the subfloor, now the product is really floating and can crack in the middle of the product where the hump is at--not just the locking mechanism.

Now, some of this can be mitigated with the thickness of the board, as alluded to in the last paragraph. Click-together has a sweet spot, where you don't want the product to be too thin or too thick. You want something around 7mm to maybe 10mm because too thin, the locking mechanism does not have a lot of support and is more likely to break over time and too thick, the product is too dense and does not do well with any change. You have to be even more vigilant with products not in that sweet spot to make sure the locking mechanism stays strong and linked together because if one board has its mechanism break, then the rest of the floor is put at massive risk of breaking as well. It's like a domino effect.

Finally, click-together products can creak, regardless if it is LVP or not. The creaking noise is coming from the mechanism and floating aspects of the floor. Though these issues are possible to fix in some instances, the squeaking in the meantime can be frustrating. The soundproofing of the floor, because of the floating qualities, aren’t great either. Some underlayment barriers can help mitigate this problem, but that’s when you start reaching an additional $2-3 or more per square foot.

Glue-Down

Unlike rigid core products, glue-down must adhere to the subfloor. If the product is not glued-down, it can shift around and basically have a mind of its own. The edges do not have a mechanism to keep them together, so glue is used to keep them in place.

Unlike rigid core products, glue-down must adhere to the subfloor. If the product is not glued-down, it can shift around and basically have a mind of its own. The edges do not have a mechanism to keep them together, so glue is used to keep them in place.

Pictured is Karndean Opus in Leyster Oak WP425

Pros of Glue-Down

For the most part, you can take of the cons of a rigid core product and flip it around to describe glue-down’s pros. Let’s take the last point of the click-together, for instance. Glue-down does not have a piece that overlaps with another board in any way, shape, or form. Rolling chairs are going to preform better on the floor without causing a major beating in the process, heavy furniture like pianos can be placed with ease without stressing whether or not the planks will be crushed under the weight, dragging furniture shouldn’t cause the planks to be pulled apart from one another, and so on. If one board fails, the one board fails.

…if one board fails, the one board fails. Literally. Say there is a flood in your basement, and you have a glued-down LVP product. You are worried the subfloor got damaged during the flood, so now you have to rip up the planks. Because the product is glued-down, you can replace individual boards. You can pull up one board, even if it is in the middle of the room, and replace it without causing the rest of the floor to fall into a kerfuffle. In fact, for most glue-down products, you can actually reuse the board. Pulled up some planks to dry out the subfloor? If you let the plank dry out as well, make sure there is no mold growth going on (most flooring retailer-only products already have an antimicrobial backing going on, so bacteria growth is less likely to occur in this instance), reapply a layer of glue, the exact same plank can be put back into place once ready. Going a step further, if you are extremely careful when ripping out a glue-down floor, you might be able to reinstall the sample planks. That’s not always recommended for various reasons and probably is not worth the hassle of reinstalling the old floor again, but it is possible. Rigid core may be easier to rip out, but most boards will break in the process.

Going back to the flood, glue-down products typically have a better water proofing and noise dampening features than other products because there isn’t near as much room between the subfloor and the product itself for water to become a major problem or for sound to bounce around. Most instances, waterproofing matters more on the backside of the floor where you don’t see, though the top is a nice perk and often a side-affect of what waterproofing has been done on the back of the plank. Furthermore, the glue for most glue-down products also acts as an additional moisture barrier, meaning there is another added layer of protection built-into the installation process of the product itself.

Glued-down floors also don’t need an expansion gap, usually found under the baseboards for click-together products. They aren’t going to move around because they are adhered to the subfloor, so no need to worry about having a gap in case the floor needs to move around due to expanding and contracting with temperature changes. This isn’t to say temperature and humidity no longer matters, as those influences can still cause other problems outside of the board changing shape and size. That’s a nonnegotiable for any type of flooring material, even carpet believe it or not. Regardless, without the need for expansion gaps, glued-down products are more dimensionally stable. They aren’t rigid, so they can adjust alongside the subfloor as time goes on. The board won’t crack because a hump appears, unlike rigid products. Even if it did, you can replace it!

For our last point, glue-down products can be laid however you want. Herringbone, chevron, parquet patterns, tile-looks mixed into the pattern—you name it. The glue is what keeps it in place, so if you can lay down the boards to the pattern or even shape that you want, you can do it. Check out some of Karndean’s unique design options here and for a look into what custom ideas they can help bring to life here.

Cons of Glue-Down

Glue-down is less likely to be a good temporary option, though it can be in some instances. When removing, the prep to remove the glue may be a little bit more work than if you were using a rigid core product, but depending on why the floor was temporary in the first place and what was underneath, this probably won’t be that big of a problem. After all, all floor needs prepped every time something is torn out and installed.

In terms of DIY installation, this one can be more tricky. Depending on the gluing method, trowel versus roller, the timing of laying down the glue to the product can be hard to figure out and grow accustomed to. Furthermore, glue can be tricky to remove if the product is splattered on the walls, so the installer has to be aware of what is going on around them to make sure they clean up any accidental spatters before it dries.

As for cost, glue down can be higher than some rigid core products, but glue down tends to have a more narrow price point than other options. Much like rigid core products, though, there is the cost of the additional material required, and in this case, the cost of glue. When breaking down the cost of glue into square footage, it ends up being $0.50 additional. We at Bonsai use a dry-set glue, and the cost for us is about $0.50-1 using a higher-end option, so in reality, it’s about the same additional charges that come along with the underlayment options for click-together.

Loose Lay

Loose lay is taking the best of glue-down and the best of rigid core, then putting them together into one product. We aren’t even kidding. Loose lay does not have a locking mechanism but can be laid right up against one another without gluing the entire floor down. (You do have to glue the very edges of where the floor will go, so some glue is required. No where near the required amount, though.) However, you can glue down the product. The reason you can do either comes down to the backing, where loose lay typically has a textured pattern that gives the plank traction to prevent them from moving while also providing groves for glue to better adhere to.

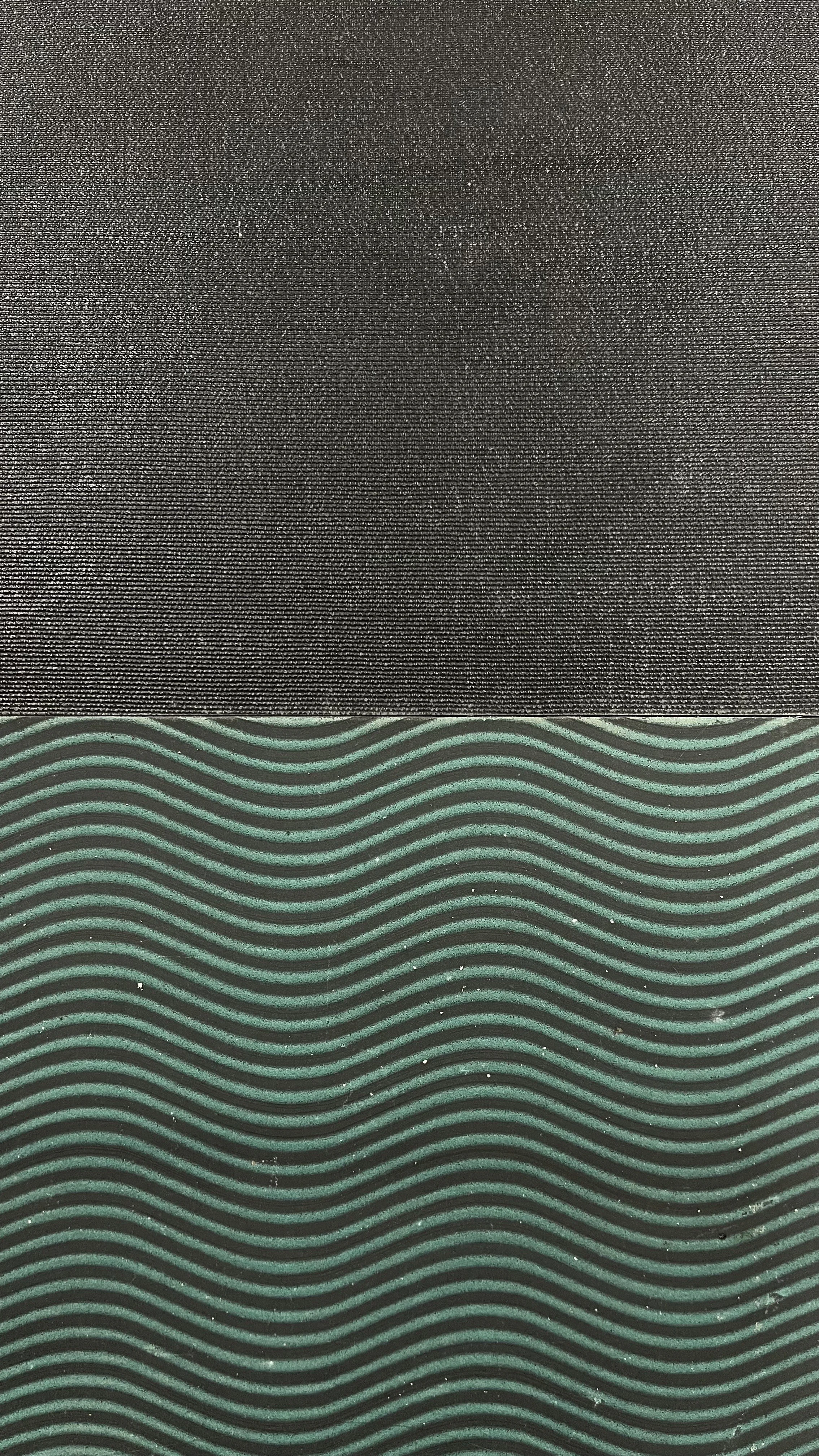

Pictured: Top is the backing of a glue-down product, whereas the bottom is the backing of a loose lay product.

Pros of Loose Lay

Not only does loose lay have two different options for you to install, depending on your needs, but it can outperform the life of glue-down and rigid core if installed properly and in a similar style as their comparison. Because of the extra texture on the back, the product is less likely to move around while also being highly dimensional stable to any changes going on, no matter what side is facing changes. When it is glued down, that becomes an even bigger strength for a loose lay product.

A loose lay product also does not require an expansion gap, no matter how you install the product. In fact, if there is a gap along the edges of the floor when installed, the floor will more than likely fail because of the way the product is designed; loose lay is meant to take on a lot of force on each side of the product (ignoring the face and back), so if any of the product is loose, ironically enough, the force is not high enough to keep the product in place. In other words, you want the loose laid floor to be as tight and scrunched together as possible. Really ironic, if you ask me.

Loose lay can also work well as a permenant or temporary floor because glue is optional. If you need a temporary floor but are a little hesitant to go with the risks of a rigid core product because you have a lot of heavy furniture and roller wheels, a loose lay floor not glued down (or at the least with only one layer of glue for that extra added security) may be a good option for you. Gluing it down can also make for a better “temporary” option compared to a glue-down product, as you may not need to use as much glue or can get by with a single layer instead of double, like the recommended amount for going for a pure-glue down as a product or for loose lay.

Furthermore, loose lay is a lot like glue-down, arguably more like glue-down versus click-together, and has a greater waterproofing and noise reduction ability compared to rigid core. The force between planks helps against water from seeping through the space between the planks, and because the product is less like floating and more like a permanent adherence to the subfloor, glue or not, water is less likely to be a concern on the back where you can’t see. Furthermore, loose lay can have the benefit of having a antimicrobial backing found on most rigid core floors and professional grade glue-down.

Even though the planks are supposed to be pressed against each other for a snug fit, they can still be individually replaced like a glue-down floor. This is not like a click-together product where removing one can cause the whole floor to unclick, but instead, the board and be removed and replaced—easier so if the floor is glued-down instead of loose laid. A scratch board doesn’t have to be an eyesore if you’ve got an extra box or two leftover to replace that one pesky plank. Going a step further, a plank can be reused, for as long the mechanisms of the plank are still in good condition (the back still has texture is essentially one of the only requirements. And if the plank itself isn’t cracked, that matters, too).

Loose lay can be placed down in any parquet pattern you can dream of. Herringbone is a classic option, as well as chevron and parquets with stone look-alikes placed in the mixed. The design possibilities, like glue-down, are limitless. As long as the planks are snug and glued on the edges of the room, anything is possible.

Finally, loose lay can be an extremely budget friendly option. Though a little bit more than the lowest grade click-together price point per square foot, loose lay can often be a cheaper alternative to a pure glue-down only product but provide the exact same benefits to a glue-down, especially if the product is in fact glued down.

Cons of Loose Lay

In all reality, the cons of loose lay can be fixed by using glue. If temperature and humidity is not properly regulated, the planks can still change size and leave gaps. Except, unlike rigid core, when this happens with loose lay, the gaps can disappear completely if those enviromental factors are brought back to the proper range and maintained. The gaps will disappear as if nothing happened. Furthermore, the annoying gap problem can be fixed entirely if the product is glued down instead of simply loose laid. Having the product be a tight glue-down will remove this as a problem and be less of a concern over time. However, that does not mean the temperature and humidity can be whatever. This simply means the problem will be less likely to appear. Going a step further, though this is much less common, loose lay can be epoxied to the floor, which works great in sunrooms where the temperature is usually more drastic and has the sun beating down on the product all day. If the product is epoxied instead of glued, that becomes even less of a concern, as now the product can essentially withstand nearly anything. (PS, loose lay is the only product on the market that can be safely epoxied without voiding the warrnaty. If you’ve got a sunroom and want to have LVP installed in there, this will be your safest bet. Just double check with the manufacturer that their loose lay product can be epoxied.)

Glue on the edges of the space where the loose lay is installed can emit VOCs, which can be a concern for those concerned over health both during and post installation, as well as the environment. Though there are glues on the market that emit a neutral gas and have a minimal impact on the environment, the smell can still be a concern in some instances. However, unlike glue-down, the less glue you can get by with, the less of a concern this may be for some people. For a large room, a small gallon buck of a dry-set, single layer of glue around the edges will likely be enough for product to perform well, while also keeping VOCs to a minimum.

Finally, the cost can fluctuate a little bit more, depending on whether or not glue is used to install the product. The price may go up an additional $0.25 per layer of glue, up to two layers, per square foot, meaning the price overall, if fully gluing down a loose lay product, will go up $0.50 per square foot. Because a layer around the edges on the subfloor is required, there is a minimum of that perimeter square footage is times by at least $0.25 added onto the total cost.

Final Thoughts

Most of the time, loose lay products are probably the way to go, if you are looking into getting an LVP. They are the most versatile product on the market and perform well in so many instances with little to no issue. However, that isn’t to say other installation method products are not great. Click-Together works well if you need a temporary floor, prefer something more rigid, or want a product that is more DIY friendly that you can feel confident installing. Glue-down can be the better choice if you are looking for something more permenant than loose lay.

There are a lot of reasons someone may choose one over the other because each space has different needs. Loose lay is more likely to fit those needs, but there can still be downfalls where either glue-down or rigid may be better. Sometimes it can just come down to color options that one product type has that the other doesn’t, and that can play the biggest role in choosing a product anyway. Ultimately, if you like the feel, color, price, and overall a product more than another, regardless of how it is installed, that product will probably be better for you than trying to pick a product based purely on the installation method. Afterall, if a floor is prepped just right for the product being installed and the floor is taken care of after the installation is said and done, perhaps the pros and cons of each type doesn’t matter at all. There are ways to mitigate their problems, and a good flooring expert can tell you what needs to be done for each product you are looking at. These little pros and cons can matter, but they don’t have to completely determine or play that big of a role in what works best for you, for the space you are curating.